Magnets, especially their invisible forces and remarkable abilities to attract or repel objects without physical contact, have long fascinated humans, hence our continued interest in them. But we also have to mention their numerous applications in our daily lives. Now, among the different types of magnets, electromagnets and permanent magnets do hold significant importance in various aspects of modern life. From precast concrete formwork to the motors that propel our vehicles and the generators that illuminate our cities, these magnets lie at the heart of these remarkable inventions. But what are these magnets? What are their applications and characteristics? This is what we are going to cover in this article! We want to help you appreciate their unique contributions to science, technology, and everyday life.

Understanding Electromagnets

Definition and constructions

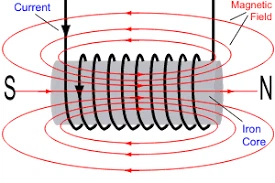

Let's start by defining what electromagnets are! So, electromagnets are magnets that are created by the flow of electric current through a coiled wire that is often wound around a ferromagnetic core, which enhances the magnetic field produced by the current. The ferromagnetic core, which is typically made of iron or steel, essentially serves to concentrate and amplify the magnetic flux that the electromagnet generates. With regards to the construction of these magnets, it can vary depending on the specific application and desired magnetic field strength. Some of the elements/factors that can influence this construction include

vThe core material – first and foremost, the material greatly affects the magnetic properties of the magnet. So, ferromagnetic materials like iron, steel, and nickel are commonly used as they have high magnetic permeability, which means that they can conduct and concentrate magnetic flux efficiently. Also, different core materials have varying saturation levels and coercivity, which can impact the maximum magnetic field strength that can be achieved.

vWire gauge and turns – the gauge, or thickness, of the wire, used is also very important. The reason being, thicker wires can handle higher currents and generate stronger magnetic fields, but they may require more space and have increased resistance. What's more, the number of turns in the coil also influences the strength of the magnetic field, where more turns in the coil could enhance the magnetic field but may also increase resistance while limiting current flow.

vCoil configuration – this can vary depending on the desired characteristics of the magnetic field. First, the coil can be wound in different ways, which includes single-layer solenoid or a multi-layer helical coil. Also, the shape and arrangement of the coil can affect the distribution and concentration of the magnetic field. And for specific applications, custom coil configurations may be designed to achieve optimal magnetic field properties.

vPower source and control circuitry – last but certainly not least, the source of power and control circuitry also plays a crucial role in the construction of electromagnets. For the power source, it can be a direct current supply or alternating current source, and the control circuitry may include things like switches, relays, or electronic components to regulate the current flowing through the coil, thereby allowing for an on/off control or adjustment of the magnetic field strength.

· Electromagnetic Fields

When it comes to electromagnetic fields, they are generated around the wire when an electric current flows through the wire of an electromagnet. This magnetic field is essentially characterized by its strength and direction, where you find that the strength is directly proportional to the magnitude of the electric current passing through the wire. What we mean is that by increasing or decreasing the current, the strength of the magnetic field can be controlled. As for the direction of the magnetic field, it is determined by the direction of the electric current flow in the wire.

· Control and Strength

One of the key advantages of electromagnets is their ability to have precise control over their magnetic properties. You see, by adjusting the electric current flowing through the wire, the strength of the magnetic field can be altered accordingly. This dynamic control allows electromagnets to generate magnetic fields that range from weak to exceptionally strong. In addition, the ability to manipulate the strength of the magnetic field provides versatility in various applications where precise and adaptable magnetic forces are required.

· Applications

Lastly, we need to look at the applications of electromagnets And we begin by stating that these magnets are used in numerous fields and industries.

vFor starters, in precast concrete, electromagnets can be utilized to provide the necessary magnetic force to hold the formwork or molds in place during the casting process.

vThey are widely used in the magnetic separation process to extract ferrous materials from non-ferrous materials.

vThey are also used in lifting systems to handle and transport heavy loads with ease.

vElectromagnetic clutches and brakes are used in machinery to transmit torque or control motion by engaging or disengaging the magnetic field.

vIn transportation, electromagnets play a vital role in magnetic levitation trains, where magnetic fields are used to suspend and propel the train without traditional wheels. Magnetic braking systems in trains and vehicles also employ electromagnets for efficient deceleration.

vThey are also used in medical devices, such as magnetic resonance imaging (MRI) machines, where strong and precisely controlled magnetic fields are utilized to visualize internal body structures.

Advantages of Electromagnets

v The magnetic properties of electromagnets can be easily adjusted by changing the electric current.

v Electromagnets offer the advantage of magnetism that can be turned on and off.

v Strong Magnetic Field: Electromagnets can generate powerful magnetic fields.

v These magnets can be shaped into different configurations to suit specific applications.

Disadvantages of Electromagnets

v Power Dependency: Electromagnets rely on a continuous power supply to maintain magnetism.

v Heat Generation: Electric current flowing through electromagnets can generate heat, requiring heat management measures.

v Limited Range: The strength of the magnetic field diminishes rapidly with distance from the electromagnet.

v Complexity: Electromagnets require additional components and can be more complex compared to permanent magnets.

Understanding Permanent Magnets

· Definition and Composition

Let's begin by understanding what permanent magnets are by definition. So, in simple terms, Permanent magnets are magnets that retain their magnetism over an extended period without the need for an external power source. The magnets are typically made from materials that have ferromagnetic or ferrimagnetic properties, which includes alloys such as neodymium iron boron (NdFeB), samarium cobalt (SmCo), and ceramic magnets like ferrite magnets. With regards to the composition of these magnets, it all depends on the specific type of magnet. For instance, NdFeB magnets are composed of an alloy containing neodymium, iron, and boron, which results in magnets with exceptional strength, high coercivity, as well as excellent magnetic properties. Another common magnet is the SmCo magnet, which is basically composed of an alloy of samarium and cobalt, along with traces of other elements such as iron, copper, and zirconium. SmCo magnets exhibit strong magnetic properties, high coercivity, and good temperature stability.

· Magnetic domains

At the microscopic level, permanent magnets are composed of tiny regions that are commonly known as magnetic domains. These domains consist of groups of atoms or molecules that align their magnetic moments in the same direction, which, in turn, creates a coherent magnetic field within the domain. When in an unmagnetized state, the magnetic domains are randomly oriented, which results in a net magnetic field of zero. But when the magnet is magnetized, the domains simply align perfectly, thereby producing a strong and stable magnetic field.

· Magnetic properties

The other thing is that permanent magnets exhibit several magnetic properties that define their performance. The most important property is magnetization, which refers to the strength of the magnetic field generated by the magnet. The other properties include coercivity, which measures a magnet's resistance to demagnetization, and remanence, which indicates the residual magnetic field retained after external magnetic fields are removed. Essentially, the magnetic properties of these magnets are influenced by their composition, manufacturing processes, and temperature.

· Applications

Now, permanent magnets offer a multitude of applications across various industries, which includes the following;

v Permanent magnets can also be used in precast concrete, where they provide a strong magnetic force to hold the formwork or molds together and in place during the casting process. Basically, the magnets maintain their adhesion even under the weight and pressure of the concrete, providing reliable support.

v In electrical engineering, where they are used in motors, generators, and transformers to convert electric energy into mechanical energy and vice versa.

v They are also used in speakers, headphones, and microphones, where they convert electrical signals into sound.

v They are also used in the medical field in Magnetic Resonance Imagining (MRI) machines for medical diagnostics.

v Magnetic fasteners, magnetic levitation (maglev) transportation systems, and magnetic separators are among the many other applications where permanent magnets play a crucial role.

Advantages of Permanent Magnets

v Permanent magnets provide a consistent magnetic field without the need for an external power source, ensuring continuous operation.

v They are durable and resistant to environmental factors such as temperature, humidity, and vibrations, making them reliable in various industrial and electronic applications.

v The magnets exhibit high energy conversion efficiency, enabling effective conversion of electrical energy into mechanical energy and vice versa.

v Despite their compact size, permanent magnets offer strong magnetic fields, making them ideal for applications with limited space requirements, including electronic devices, sensors, and magnetic storage.

Disadvantages of Permanent Magnets

v Magnetic properties are fixed, limiting their versatility in applications requiring variable or controllable magnetic fields.

v Permanent magnets have temperature limitations, and high temperatures can degrade their magnetic properties.

v Some permanent magnets can be challenging to magnetize or demagnetize, requiring specialized equipment and techniques.

v Certain permanent magnet materials, like certain types of ceramic magnets, are brittle and prone to chipping or breaking under mechanical stress.

A Comparative Analysis

Now that we understand what each category of magnets entails, let's take a look at how they compare against one another. There are three main elements, which they differ, and they are as follows;

· Strength and control

So, as we have already mentioned, one of the key advantages of electromagnets is their ability to provide variable strength and control over the magnetic field. Now, when you adjusting the electric current flowing through the wire, you can be able to control the strength of the magnetic field precisely. This essentially allows electromagnets to generate magnetic fields that ranges from weak to extremely strong, which, in turn, offers versatility for different applications. In addition, the magnetic field can also be easily turned on and off by controlling the electric current, which now provides instant control and manipulation. On the other hand, when it comes to permanent magnets, they have fixed strength that is determined by their composition and manufacturing process. And once they have been magnetized, the magnetic field of the magnet remains constant without the need for external power. However, the strength of these magnets cannot be adjusted or controlled after the manufacturing process, as they provide a steady magnetic field that is predefined based on their composition and cannot be easily changed.

· Energy requirements

Talking of energy requirements, electromagnets require an external power source to generate a magnetic field. Now, the amount of energy consumed by an electromagnet depends on the strength of the desired magnetic field as well as the duration of its use. Higher magnetic fields or continuous operation of electromagnets will obviously require more energy input. However, we need to remember that electromagnets are able to turn off the power supply, thereby resulting in zero energy consumption when the magnetic field is not needed. As for the permanent magnets, they do not require any external power source to maintain their magnetic field. As we've already mentioned, once the magnets are magnetized, they are able to sustain their magnetic properties without any energy input. This means that these magnets are energy efficiency as they operate independently without the need for continuous power supply or control.

· Reliability and durability

When it comes to reliability and durability, electromagnets do fall short as they experience a few limitations. Remember how we said that these magnets need a power supply to create a magnetic field? Well, these magnets rely on the integrity of the electrical circuit and the power supply for their operation. This means that a failure or interruption in the electrical circuit or power supply will certainly result in the loss of the magnetic field – which is something no one wants. In addition, electromagnets are more susceptible to heat and can be prone to demagnetization at high temperatures, not to mention that the coil winding and connections may experience wear and tear over time, all of which directly affects their reliability. For permanent magnets, the opposite is true! I mean, these magnets are known for their high reliability and durability. Once they are magnetized, they basically exhibit a stable magnetic field that is completely not reliant on external factors. So, unlike electromagnets, permanent magnets are just not susceptible to power supply interruptions or circuit failures. Last but certainly not least, the magnets are more resistant to heat and are able to maintain their magnetic properties even at elevated temperatures, which, in turn, gives them a longer operational lifespan and require minimal maintenance.

So, to summarize, we can say electromagnets will give you the possibility to adjust the magnet’s strength, instant control, and the ability to turn the magnetic field on and off, but you will need an external power source for it to work. This means that they can be interrupted if the power source fails, making it less reliable. As for the permanent magnets, they provide a constant magnetic field without the need for a power supply or control but lack the flexibility to adjust their strength. They are, however, highly reliable and durable, offering energy efficiency and long-lasting performance.

Conclusion

In conclusion, as you can see, both of these categories of magnets do offer distinct advantages, especially when it comes to their applications. Considering their strength, control and versatility, you will be able to apply them in various applications, which can include precast concrete, transportation, manufacturing and engineering. So, if you are looking to choose between them, just know that your choice will depend on your specific needs. Also, you need to determine whether you will be going for dynamic control or is it independent durability? Whichever it is, just know that you stand to gain so much from the magnets.