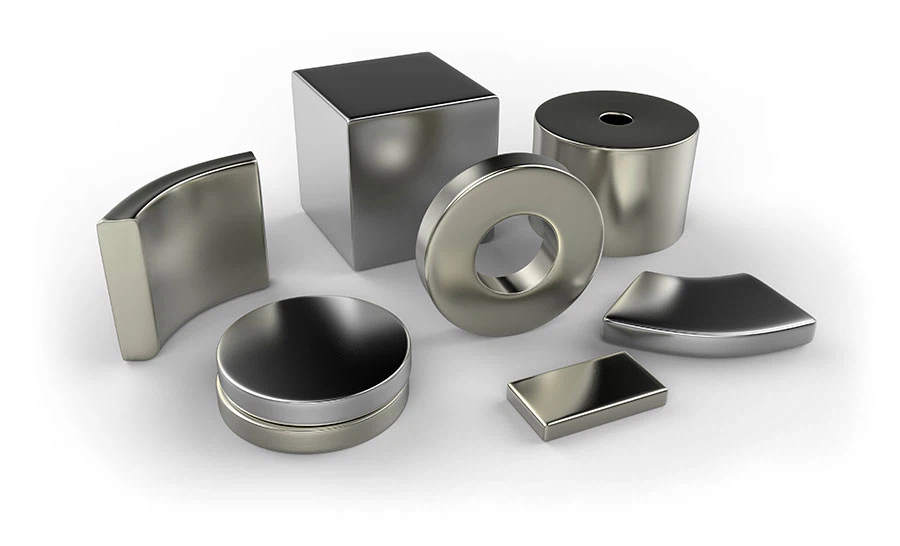

Magnets are among the most robust materials on the planet, with some of the strongest attracting objects over six hundred times their weight. They come in various shapes and are essential in many applications.

There are two main types of magnets: bonded and sintered. Bonded magnets are made by mixing the magnetic powder with a binder and molding it. This process provides high dimensional accuracy and mechanical strength, making them ideal for motors, phones, and office equipment.

Sintered NdFeB magnets are created by sintering powdered materials into solid blocks, which are then shaped and magnetized. Sintering is a process where powdered materials are heated just below their melting point to bond and form a solid structure. Because of this, sintered magnets offer superior magnetic strength but come with higher production costs and lower dimensional accuracy.

Understanding these differences helps in choosing the right magnet type for your needs, from industrial machinery to consumer electronics. Each type has unique advantages and is suited for different applications. Below, we will talk about these two magnets, and give you a comparison to help you understand what they can do in this sintered vs. bonded magnets debate.

Understanding Bonded Magnets

Bonded magnets combine the strength of magnetic powders with modern manufacturing techniques, resulting in adaptable magnets. They are composed of Nd2Fe14B magnetic powder mixed with a binding agent, such as a polymer or resin, shaping them into different forms.

Definition and Basic Properties

Bonded magnets are made from a mixture of neodymium (Nd), iron (Fe), and boron (B), collectively known as Nd2Fe14B. This magnetic material is combined with a binder, which holds the particles together and forms a precise and intricately shaped magnet.

Manufacturing Process

The manufacturing of bonded magnets involves three main steps:

Mixing: The Nd2Fe14B magnetic powder is blended with the binding agent to create a uniform mixture.

Molding: This mixture is injected into a mold or compressed into the desired shape.

Curing: The molded mixture is cured to solidify the binder and lock the magnetic particles in place.

Types of Bonded Magnets

Bonded magnets are categorized into two types: isotropic and anisotropic. Sotropic Bonded Magnets have the same magnetic strength in all directions. They are usually less powerful but easier to make. Anisotropic Bonded Magnets, on the other hand, are designed to be stronger in one specific direction. They are more potent in that direction but need more precise manufacturing techniques for better performance.

Applications and Use Cases

Bonded magnets are very versatile and used in many different ways because they are easy to make:

Office Equipment: Used in printers, copiers, and other office devices for precise operation.

Small Motors: Found in household appliances and toys, where their small size and reliable performance are beneficial.

Sensors: Important in cars, industrial machines, and consumer electronics to detect and measure magnetic fields for accurate readings and controls.

Advantages and Disadvantages

|

Advantages |

Disadvantages |

|

Made through molding processes, achieving precise dimensions for applications requiring exact shapes and sizes. |

Generally have lower magnetic strength compared to sintered magnets, limiting their use in high-performance applications. |

|

Less expensive manufacturing process compared to sintered magnets, making them ideal for many applications. |

May have lower thermal stability, affecting performance in high-temperature environments. |

|

Can be molded into complex shapes and sizes, useful for custom applications. |

The binder can affect mechanical strength and durability, making them less suitable for high-stress applications. |

Understanding Sintered Magnets

Sintered magnets are among the most powerful and widely used in modern technology, known for their high magnetic strength and performance.

Definition and Basic Properties

Sintered magnets are composed of Nd2Fe14B, a combination of neodymium, iron, and boron. This results in magnets with very high density and superior magnetic properties, making them ideal for industries that require powerful magnetic fields.

Manufacturing Process

The manufacturing of sintered magnets involves a process called powder metallurgy, which includes two main steps:

Compaction: The Nd2Fe14B powder is compacted under high pressure to form a dense "green" shape.

Sintering: The compacted shape is heated at high temperatures, causing the particles to fuse, increasing density and magnetic properties.

Grinding: To achieve the desired shape and size, sintered magnets often need to be ground down with precision tools.

Coating: Sintered magnets are usually coated to prevent corrosion, with common coatings including nickel, zinc, or epoxy.

Types of Sintered Magnets

Sintered magnets come in various types, each suited for different applications:

NdFeB (Neodymium-Iron-Boron): The strongest type of permanent magnet, ideal for high-performance applications.

SmCo (Samarium-Cobalt): Offers excellent thermal stability and corrosion resistance, suitable for high-temperature applications.

Ferrite (Ceramic): Made from iron oxide and barium or strontium carbonate, known for cost-effectiveness and good resistance to demagnetization and corrosion.

Alnico: Composed of aluminum, nickel, and cobalt, with high magnetic strength and excellent temperature stability, though more easily demagnetized.

Applications and Use Cases

Sintered magnets are used in a lot of industries due to their strength and reliability:

Medical Devices: Used in MRI machines to produce detailed body images with strong magnetic fields.

Industrial Machinery: Found in electric motors and generators, converting electrical energy to mechanical energy and vice versa.

Aerospace: Used in parts like actuators and sensors, providing high performance and reliability in harsh conditions.

Sintered magnets are indispensable in modern technology, providing the necessary strength and stability for a variety of high-performance applications. Their unique properties make them important in many advanced devices and systems.

|

Advantages and Disadvantages |

||||||||

|

Critical Differences Between Sintered and Bonded Magnets

When choosing the right type of magnet for a specific application, you must understand the fundamental differences between both magnets. These differences influence their performance, cost, and suitability for various uses. Let's explore the sintered vs. bonded magnets differences in detail.

Surface Magnetism

Sintered magnets have a strong magnetic pull on their surface because they are dense and compact. This makes them ideal for high-performance uses like electric motors and MRI machines, where strong and stable magnets are needed. They are often designed to work best in specific directions, increasing their performance in those orientations.

Bonded magnets have a weaker surface magnetism because they include a polymer binder, which makes them less dense. However, they can be easily shaped and are cheaper to produce. They can have a uniform magnetic strength or a preferred direction, making them suitable for items like consumer electronics, small motors, and sensors, where flexibility in shape and moderate magnetic strength are important.

Material Composition and Properties

Sintered magnets are made from compacted and heated magnetic powders, resulting in a dense and robust structure. They are primarily composed of materials like NdFeB (Neodymium-Iron-Boron) and SmCo (Samarium-Cobalt), known for their high magnetic strength and thermal stability.

In contrast, bonded magnets are composed of magnetic powder mixed with a binder, such as a polymer or resin. This allows for flexibility in shape and size but results in lower density and magnetic strength compared to sintered magnets.

Manufacturing Processes

The manufacturing process for sintered magnets involves powder metallurgy, where the magnetic powder is compacted under high pressure and then sintered at high temperatures. This process results in a densely packed magnet with higher magnetic properties.

On the other hand, bonded magnets are produced by mixing the magnetic powder with a binder and molding the mixture using injection or compression molding techniques. This process is more straightforward and more cost-effective, allowing for the production of magnets with complex shapes without the need for additional treatments.

Physical Characteristics

Sintered magnets boast high strength due to their dense structure, making them ideal for applications where strong magnetic fields are required. However, they are brittle and can break easily if not handled carefully. They also need protective coatings to prevent corrosion.

Bonded magnets, in this case, are more flexible and durable due to the binder in their composition. This makes them easier to mold into precise shapes and sizes, with inherent corrosion resistance reducing the need for additional coatings.

Performance in Different Applications

Sintered magnets, with their superior magnetic strength, are perfect for high-performance applications such as electric motors, generators, and MRI machines. They maintain strong magnetic fields even at high temperatures, making them ideal for demanding industrial and medical environments.

Bonded magnets, while not as strong, excel in applications where precise shapes or sizes are needed, such as sensors, office automation equipment, and small electric motors. Their ease of manufacturing and cost-effectiveness make them a popular choice for consumer electronics and automotive sensors.

Cost Implications

Sintered magnets are generally more expensive to produce due to the complex and energy-intensive sintering process. The need for post-sintering treatments like grinding and coating also adds to the overall cost.

Bonded magnets are cheaper to make. The molding process is easier and uses less energy, and binders lower material costs. This cost-effectiveness makes bonded magnets a good choice for many uses, especially where super-strong magnets aren't needed.

Environmental Impact

Sintered magnets require more energy to manufacture due to the high-temperature sintering process, which can lead to higher greenhouse gas emissions. Additionally, the waste generated from grinding and other post-sintering treatments is often significant.

Bonded magnets, however, are more environmentally friendly in their production. The lower energy requirements of the molding process and the reduced material waste contribute to a smaller carbon footprint. Furthermore, the ability to use recycled materials in the binder adds to their environmental sustainability.

Understanding these key differences helps in making informed decisions when selecting the appropriate type of magnet for specific applications. Each type offers unique advantages and trade-offs, making them suitable for different uses and environments.

So, to recap, here is what the differences are:

|

Aspect |

Bonded Magnets |

Sintered Magnets |

|

Surface Magnetism |

Weaker magnetic pull on their surface due to the binder, suitable for complex shapes and cheaper to produce |

Strong magnetic pull on their surface due to being very compact, ideal for high-performance uses |

|

Material Composition |

Made by mixing magnetic powder with a binder like a polymer or resin, allows for flexible shapes but weaker |

Made by pressing and heating magnetic powders like neodymium, iron, and boron, making them very strong |

|

Manufacturing Processes |

Made by mixing, molding, and solidifying the material, simpler and cheaper, allows for complex shapes |

Made by pressing and heating the powder, results in tightly packed magnets, and often needs extra steps like grinding and coating |

|

Physical Characteristics |

Flexible and durable due to the binder, easy to shape precisely, resists corrosion without extra coatings |

Very strong but can be brittle, needs protective coatings to avoid rusting |

|

Performance in Applications |

Best for exact shapes or sizes needed in sensors, office equipment, and small motors, cost-effective |

Perfect for high-performance uses like electric motors, generators, and MRI machines, stays strong at high temperatures |

|

Cost Implications |

Cheaper to produce due to simpler process and lower energy use, binders lower material costs |

More expensive due to complex and energy-intensive process, additional steps add to the cost |

|

Environmental Impact |

More environmentally friendly with lower energy use and less material waste, can use recycled materials |

Larger environmental impact due to high energy use and significant waste |

Conclusion

When deciding between sintered vs. bonded magnets, it's important to think about what you need for your specific use. Consider how strong the magnet needs to be and how precise the shape must be. Your budget is also a key factor; some magnets are cheaper to produce than others. Additionally, think about the environmental impact of each type of magnet. Bonded magnets might be less powerful, but they are often cheaper and more environmentally friendly, making them suitable for a variety of applications. So, have a good idea of what you need before making your investment, or have a look at what professionals say.