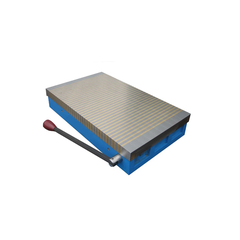

Pipeline iron separator performance characteristics

Pipeline iron separators are mainly divided into three categories: pipe-type permanent magnet automatic iron remover, pipe-type manual iron-unloading permanent magnet separator, liquid or slurry pipeline separator.

The pipeline type iron separator can effectively remove ferromagnetic impurities from pneumatically conveyed materials or a large number of materials that can freely fall by gravity, and can be conveniently installed on the transmission pipeline through flanges, square interfaces, etc. to efficiently remove particulates. Ferromagnetic impurities in powdered materials.

When the material evenly passes through the work area of the pipe separator, the non-magnetic material flows along the pipe, and the magnetic material is subjected to magnetic force and adsorbed on the pipe. After a period of time (depending on the amount of adsorbed iron), the door is opened. Artificially remove iron to achieve the purpose of removing iron.

Pipeline separator performance advantages:

Strong magnetic force, can effectively infiltrate small and large iron impurities;

The use of rare earth permanent magnets, magnetic field strength, long service life;

Magnets are attached to the walls of the tank in the form of a hinge and can be opened at any time to remove adsorbed impurities.

The pipe type iron remover has the characteristics of small size, light weight, strong magnetic field, clean iron removal, no energy consumption, convenient operation and long service life. Widely used in food, pharmaceutical, roasted seeds, tobacco, chemical industry ferromagnetic impurities in the filter material to ensure the safety of the finished product.

The iron remover is connected in series with the material conveying pipeline with an inclination of 45-75 degrees. When the material flows through the iron remover, the ferromagnetic material therein is adsorbed on the stainless steel pipe wall of the iron remover of the pipe and gradually moves along with the movement of the permanent magnet. Slide in the direction of the taphole to achieve separation from the material. At the tap hole, due to the permanent magnet moving away in the direction of cyclical motion, the ferromagnetic material loses its magnetic attraction, and is discharged from the tap hole under the action of gravity to achieve automatic iron removal of the material.

The pipeline type iron separator is a high-performance automatic magnetic separation equipment, which maintains the advantages of strong magnetic force, no waste of raw materials and good iron removal effect of the existing pipeline type iron separator, and overcomes the need for manual iron removal and complicated working procedures for the existing iron remover. The disadvantage of not being able to work continuously is a new generation of energy-saving and environment-friendly products. Can be widely used in cement, electricity, ceramics, brick, chemical, food, glass, metallurgy, steel and other industries, is the preferred iron removal equipment for material purification and ensure the safe operation of the follow-up equipment.