Magnets are an essential component in numerous objects that we use daily, assisting them to work by making magnetic fields. With suitable magnets, you can build very strong magnetic things. But if you select the wrong magnets, what you build could be weak, break easily, or even be dangerous.

So, how do you determine which magnet grade is optimal for your application? Two of the most common strong magnet materials used today are neodymium N52 and N42 grades. But what's the difference? Which one is better and why? Below, we'll compare N52 vs N42 magnets to help you select the right option for your needs.

An Introduction to Neodymium Magnets

Modern neodymium-iron-boron magnets are the most powerful permanent magnets sold today. They are also referred to as NdFeB magnets. They are constructed from a meticulously formulated blend of neodymium, iron, and boron metals. Advanced manufacturing techniques are utilized to maximize their magnetic capabilities.

Some key advantages of neodymium magnets:

● Extremely powerful magnetic field for their size

● High coercivity, meaning they resist demagnetization

● Can operate at high temperatures up to ~80°C to 130°C

● Less expensive per magnetic field strength than samarium cobalt magnets

Neodymium magnets became commercially available in the early 1980s and quickly revolutionized many industries due to their unmatched magnetic power.

Grades of Neodymium Magnets

Not all neodymium magnets are created equal. They are manufactured in different grades that determine their magnetic strength. A number denotes the grade – the higher the number, the stronger the magnet.

(Grades of Neodymium Magnets)

Some common neodymium magnet grades are:

● N52 – The highest grade of neodymium magnet commercially available today with a Br max rating of around 14 MGOe (MegaGauss Oersted). N52 has the most excellent magnetic energy density.

● N50 – Slightly lower grade than N52 but with similar properties.

● N48 – The most popular neodymium magnet grade offering a good balance of magnetic strength and value.

● N45 – Mid-range neodymium magnet. It is lower in cost but approximately 30% less potent than N52.

● N42 – Low to mid-range neodymium magnet with lower magnetic properties than N45 and N48.

● N38 – Low-grade neodymium magnet. Inexpensive but weakest performance.

In summary, higher grade numbers indicate stronger magnets. The highest grade neodymium magnet commercially available right now is N52.

N52 Magnets

N52 represents the highest-quality neodymium magnets on the market. What sets them apart?

● Maximum Energy Density

N52 neodymium magnets have the maximum possible magnetic energy density, measured in MegaGauss Oersted (MGOe). They offer a Br max (residual induction) rating of around 14 MGOe.

This means that N52 magnets generate the most robust possible magnetic fields for their size. You can create incredibly compact, powerful magnetic assemblies with N52-grade magnets.

● Excellent Temperature Resistance

Properly manufactured N52 magnets retain their magnetic strength well, even in temperatures up to ~80°C to 130°C.

They maintain a temperature coefficient of approximately -0.12%/°C, allowing them to operate routinely at higher temperatures than lower grades.

● Greatest Resistance to Demagnetization

N52 neodymium magnets have high intrinsic coercivity (Hci) of around 16 kOe (kilo Oersteds). This means they strongly resist demagnetization from external magnetic fields or impacts.

You can use N52 magnets in applications where they experience demagnetizing forces and still expect excellent magnetic performance. This grade of neodymium offers the greatest stability against demagnetization.

N52 represents the upper-performance limit of commercially available neodymium iron boron magnets today. They offer maximum energy density, temperature resistance, and resistance to demagnetization effects.

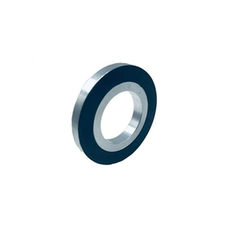

(N52 Magnets)

N42 Magnets

N42 is a lower grade of neodymium magnet positioned between N45 and N38 grades. Here are its characteristics:

● Lower Magnetic Energy Density

The Br max rating for N42 magnets falls around 12.5 to 13 MGOe. This means N42 has an energy density approximately 10-15% lower than N52 neodymium magnets.

● More Limited Temperature Range

The operating temperature range for N42 magnets is narrower compared to N52. Temperatures exceeding ~80°C can start to degrade the magnetic strength of N42-grade magnets quickly.

● Lower Demagnetization Resistance

With a coercivity rating of around 10.8 to 12 kOe, N42 magnets have lower demagnetization resistance than N52. They lose their magnetism faster when subjected to external magnetic fields or impacts.

N42-grade neodymium magnets offer reduced magnetic performance compared to N52 in energy density, temperature resistance, and demagnetization resistance. They represent a lower mid-range grade.

(N42 Magnets)

N52 vs N42 Comparison

Now, let's directly compare the differences between N52 and N42 neodymium magnet grades:

Aspects | N52 | N42 |

Corrosion Resistance | Thick Nickel Copper Nickel coating | Normal Nickel Copper Nickel coating |

Mechanical Strength | Very Strong | Strong |

Operating Temperature | Up to 80°C | Up to 80°C |

Cost | Expensive | Affordable |

Availability | Limited availability | Widely Available |

Magnetization | High saturation on manufacturing | Low saturation level |

Field Strength | High | Low |

Br | High | Low |

Hc | High | Low |

Applications | Complex | General Purpose |

Considering the above information, N52 delivers superior performance but comes at a premium price. N42 offers acceptable capabilities for many uses at lower cost but has definite performance limits versus premium N52 grade neodymium magnets.

When to Choose N52 Magnets?

N52 neodymium magnets offer today's maximum energy density, temperature stability, and demagnetization resistance. Here are some of the most common applications where N52 grade is recommended:

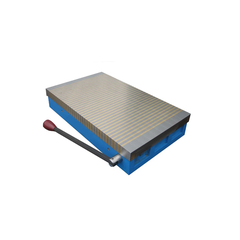

1. High-Strength Assemblies

N52 magnets offer the strongest magnetic fields possible today. For constructing robust magnetic assemblies such as lifters, separators, holders, and couplings, N52 is the premier choice. Lower-grade magnets like N42 may have difficulty properly magnetizing large, high-strength assemblies.

2. Elevated Temperature Environments

If feasible, any applications with magnets exposed to high temperatures surpassing 80°C should use N52-grade neodymium. N42 magnets become progressively more unstable and lose magnetic strength rapidly in hotter conditions exceeding 80°C.

3. Security, Safety, and Precision Systems

In systems where demagnetization poses risks of device failure, injury to users, or loss of precision, thermally stable N52 magnets are recommended. This includes components like latches, sensors, motors, and scientific instruments.

4. Maximal Power Density

N52 enables the creation of the most compact, lightweight magnetic assemblies possible. Therefore, in applications where minimal size and weight are critical factors, such as motors or portable electronics, N52 can optimize power density because of its high energy density.

5. Lifetime Cost Savings

Despite having a higher initial purchase cost, N52 magnets can save money in the long term for applications needing very stable magnetic fields. This is thanks to their excellent demagnetization resistance and thermal stability. Fewer magnet replacements are required over the operating lifetime.

When to Select N42 Grade

While N52 magnets are the premier choice in many situations, the N42 grade also has its place for more cost-driven applications:

1. Lower Power Assemblies

For simpler magnetic assemblies that don't require powerful magnetic fields, like holding signs or magnetizing tools, N42 grade can suffice at a lower price point.

2. Room Temperature Applications

If your magnets remain near room temperature from 20°C to 25°C, an N42 grade can offer adequate stability and performance for lower cost.

3. Prototyping

During the prototyping stages, N42 allows testing magnetic assemblies at a lower cost before finalizing designs around premium N52 magnets.

4. Educational Demonstrations

School science demonstrations and hobby projects focused on fundamentals rather than performance can use more affordable N42 magnets for simplicity.

5. Cost-Driven Products

For high-volume consumer products like simple refrigerator magnets, speakers, or toys where performance requirements are low but costs are paramount, N42 grade helps hit lower price points.

So, N42 magnets can be a smart choice over pricey N52 alternatives for less demanding applications where cost savings outweigh performance. Just be aware of their performance limits compared to higher grades.

FAQs about N52 vs N42

Some common questions about N52 vs N42 magnets:

Can you make an N42 magnet stronger?

Not easily. The grade represents intrinsic material properties. But you can strategically arrange multiple N42 magnets in assemblies to concentrate and amplify their fields.

What's the difference between N45 and N42 magnets?

N45 falls between N48 and N42 grades – offering intermediary properties at a lower cost than N48. But N42 has noticeably lower magnetic performance than N45.

Is an N42 magnet strong enough to lift a car?

Unlikely – the reduced magnetic field strength of N42 vs. N52 makes very heavy lifts like multi-ton vehicles highly impractical without massive arrays of magnets. Stick to N52 for serious lifting capacity.

How do you charge an N42 magnet?

You cannot "recharge" depleted neodymium magnets. But you can potentially remagnetize and partially restore weakened N42 magnets through careful exposure to strong magnetic fields. Handle with care to avoid cracking.

Conclusion

Whether you need the ultimate magnetic power of N52 grade neodymium or the cost savings of mid-range N42 depends on your application requirements and constraints. Consider your project's strength, stability, and budget, and select the grade that best balances performance and value for your needs.

With a clear understanding of their respective capabilities, you can use these two versatile neodymium magnet grades for all your magnetic assembly projects. And if you're still unsure which is a better fit, don't hesitate to talk to an expert about options tailored to your application.